How Teflon Coatings Are Used

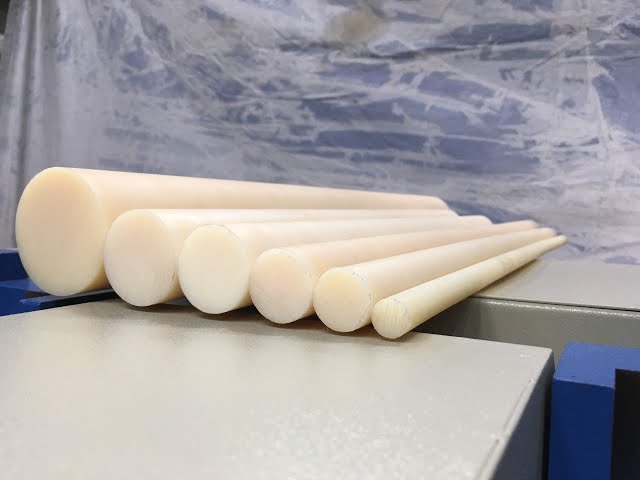

In the electrical engineering field, sourcing high-quality materials is key to enhancing the performance of wiring systems. A reliable Teflon rod supplier Singapore plays a significant role in providing the necessary components for coating and insulation in electrical wiring. These Teflon rods are known for their exceptional electrical insulating properties, chemical resistance, and durability. By sourcing Teflon materials from a trusted supplier, engineers can ensure that their wiring systems meet the highest standards for reliability, efficiency, and safety in both residential and industrial applications.

Understanding Teflon and Its Properties

Before diving into its application in electrical wiring, it’s essential to understand the properties that make Teflon an ideal material for such use. Teflon is a synthetic fluoropolymer of tetrafluoroethylene. It is well-known for its non-stick, low friction, and high resistance to heat, chemicals, and electrical currents. Teflon also exhibits a remarkable ability to maintain its strength and flexibility under extreme conditions.

Some of the key properties of Teflon that make it suitable for electrical wiring include:

- High-temperature resistance: Teflon can withstand temperatures ranging from -200°C to 260°C (-328°F to 500°F), which is significantly higher than many other materials used in wiring.

- Electrical insulation: Teflon is a non-conductive material, meaning it effectively insulates electrical wires, preventing short circuits and electrical hazards.

- Chemical resistance: Teflon is highly resistant to most chemicals, ensuring that the wire coatings remain intact even when exposed to harsh environments.

- Low friction and smooth surface: Teflon’s low friction properties reduce wear and tear on wires as they pass through conduits, ensuring smoother installation and improved long-term performance.

These properties make Teflon coatings highly beneficial for electrical wiring used in a variety of applications, from aerospace to telecommunications.

Teflon Coatings in Electrical Wiring

Electrical wiring is subjected to a variety of environmental stresses during its service life. Exposure to high temperatures, moisture, corrosive substances, and mechanical wear can significantly reduce the performance and longevity of electrical wiring. Teflon coatings help mitigate these issues, ensuring that electrical wiring performs optimally even in challenging conditions.

- Thermal Protection Electrical wires, particularly those used in industrial settings or high-power applications, are prone to overheating. Overheated wiring can lead to insulation breakdown, fire hazards, and system failures. Teflon coatings provide excellent thermal protection by withstanding high temperatures without losing their insulating properties. This makes Teflon-coated wires ideal for environments where wiring may be exposed to intense heat, such as in manufacturing plants, power plants, or automotive applications.

- Enhanced Durability and Longevity Electrical wiring is often subjected to mechanical stress during installation and operation. As wires are pulled, bent, and twisted, the insulation can wear down over time, leading to potential faults and failures. Teflon coatings significantly enhance the durability of electrical wiring by offering a tough, abrasion-resistant outer layer that protects the wire’s core from damage. Teflon-coated wires can withstand harsh environments, including exposure to UV radiation, moisture, and abrasive surfaces, which would typically degrade uncoated wires over time.

- Chemical Resistance In certain industrial environments, electrical wiring may come into contact with corrosive chemicals, oils, or solvents. Exposure to such substances can quickly deteriorate the insulation of electrical wires, leading to system malfunctions or short circuits. Teflon’s exceptional chemical resistance ensures that the coating remains intact and performs as expected, even in challenging environments where other materials would fail. This makes Teflon-coated wiring ideal for use in chemical plants, pharmaceutical manufacturing, food processing, and other sectors that deal with hazardous substances.

- Improved Electrical Insulation Teflon coatings act as excellent insulators, preventing electrical currents from leaking and reducing the risk of short circuits. Electrical insulation is crucial for the safe operation of electrical systems, as it keeps the electrical current contained within the wire and prevents it from coming into contact with other conductive materials. Teflon’s high dielectric strength (the ability to withstand electric fields without breaking down) ensures that it maintains effective insulation even under high-voltage conditions. This makes Teflon-coated wires essential for high-performance applications, including telecommunications, military, and aerospace technologies, where reliable insulation is critical.

- Enhanced Flexibility While Teflon is known for its stiffness and high-temperature resistance, it also provides significant flexibility. This makes Teflon-coated wires easier to install and more versatile in use, as they can bend and flex without cracking or breaking. This is especially important in tight spaces or when wires need to be routed through complex networks of conduits. The flexibility of Teflon-coated wires also reduces the likelihood of mechanical failure during operation, ensuring long-term reliability.

Applications of Teflon-Coated Wiring

Teflon-coated electrical wires are used in a wide range of industries and applications where performance, safety, and reliability are of paramount importance. Some of the most notable applications include:

1. Aerospace and Defense

The aerospace and defense industries require electrical wiring that can operate in extreme conditions, such as high temperatures, high altitudes, and exposure to chemicals or radiation. Teflon-coated wiring is widely used in these fields due to its ability to withstand extreme environments while maintaining electrical insulation and performance.

2. Automotive Industry

Modern vehicles have complex electrical systems that require durable, flexible, and heat-resistant wiring. Teflon-coated wires are commonly used in automotive wiring harnesses, particularly for applications such as engine compartments, where high temperatures and mechanical wear are common. Teflon’s chemical resistance also makes it suitable for use in vehicles that operate in harsh environments, such as off-road vehicles or electric cars.

3. Telecommunications

Telecommunications equipment, such as satellites, fiber optic cables, and wireless communication devices, often rely on Teflon-coated wiring to maintain signal integrity and reliability. Teflon’s low dielectric constant minimizes signal loss and ensures that electrical signals pass efficiently through the wiring, which is crucial for high-speed data transmission.

4. Medical Devices

Electrical wiring used in medical devices, such as pacemakers, diagnostic equipment, and surgical instruments, must meet stringent performance standards. Teflon coatings provide the necessary insulation and protection to ensure these devices function safely and effectively, even in high-risk environments.

5. Energy Sector

The energy sector, particularly in power plants, solar energy systems, and oil and gas operations, requires wiring that can perform under high-voltage conditions and in extreme environmental conditions. Teflon-coated wires help prevent electrical hazards, ensure long-term system performance, and reduce maintenance costs in such critical applications.

Conclusion

Teflon coatings play a critical role in improving the performance of electrical wiring by enhancing durability, thermal resistance, electrical insulation, and flexibility. Whether used in aerospace, automotive, telecommunications, or energy sectors, Teflon-coated wires ensure the safe, reliable, and long-lasting operation of electrical systems. As industries continue to push the boundaries of technology and innovation, Teflon-coated electrical wiring will remain a key material in ensuring that electrical systems perform optimally, even under the most demanding conditions. The combination of Teflon’s unique properties and its wide range of applications makes it an indispensable tool in modern electrical engineering.