Basics of Machine Shops

Fundamental Expertise of Maker Shops

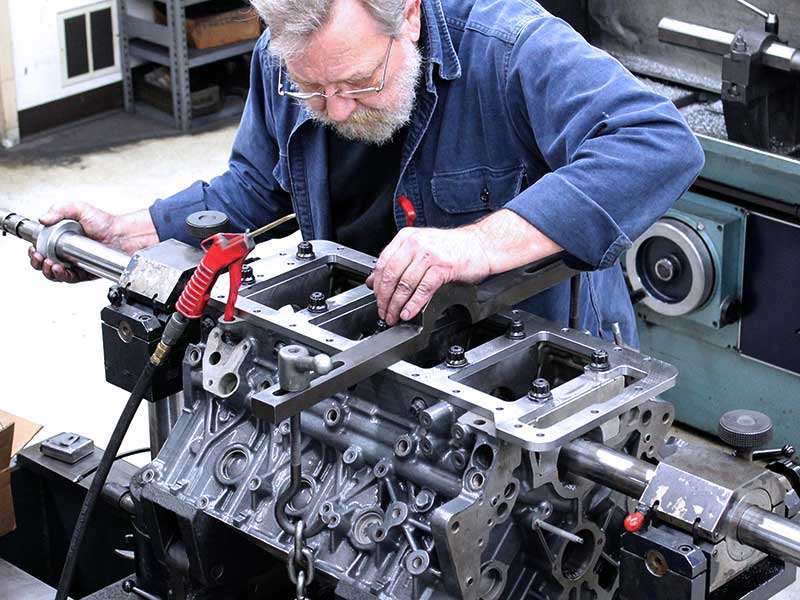

Factory remain to expand in number with the boosting quantity of things that make the factory’ solution. It could be a room, office building or open space where machining is done. Machining is the conversion of certain product with the aid of devices and also tools into a more useful item. Factory commonly contain devices and products that are distinctly utilized by the machinists.

The machinists are the ones doing the change materials. Being a machinist is in fact not a very easy job. It requires not only knowledge of the devices however the skills needed to correctly carry out the task.

The standard machine devices needed are lathes, mills, drill presses etc.

The machinists should have pertinent expertise on how to operate as well as establish the said tools for safety preventative measure. There are numerous materials dealing with turret that include collets, chucks, mandrels, faceplates as well as facilities.

The lathe does several jobs including fining sand and also drilling, reducing as well as knurling, as well as various other deformations to produce an item that has balance on rotational axis.

- Lathe is often applied in woodturning, glass jobs, metalworking, and also steel spinning, A number of objects can be made from lathe, for example: baseball bats, candle holder owners, table delays and sign sticks.

On the other hand, mills or milling machines offer for the function of shaping metal and also other strong products. Horizontal as well as vertical milling makers are used for alignment of the cutting device pin. Milling devices could be manually-operated, mechanical, automatic or digitally automated such as the computer mathematical control (CNC).

The drill area could be mounted on a stand or taken care of at the flooring.

- The standard parts of the drill are base, column, table, spindle and pierce head.

- A few of the kinds of drills are tailored head drill press, radial arm drill press as well as mill drill.

The tailored head sort of grill is operated via electrical energy wherein transfer of power from electric motor to pin occurs by spur tailoring which is located inside the head of the machine.

The head of the radial arm drill could be relocated from the equipment’s column. Mill drill is a lighter alternative to a milling device.

Machine shop covers a spectrum of self-control relying on what the store is specializing on. Nonetheless they all have main machining processes which are turning, boring and milling. The secondary tasks are forming, planning, boring, bring up and sawing.

The key procedure shall be explained below. Consequently, a round object is generated by cutting.

- The turning job part offers the transforming and also the feed activity occurs by gradually moving in a direction that is parallel to the axis of rotation. Drilling is simply the development of a rounded hole.

- The drill is put in a parallel instructions to the axis of its rotation.

- Last but not least, the uninteresting increases the size of the created opening.

The people that will significantly benefit in the factory owning are the machinists, industrial prototypes, auto restorers, R&D lab technicians, instrument manufacturers, item designers, gunsmiths, designers, inventors and also people making one-of a kind fixing parts. A newbie needs to constantly beware of his action to stay clear of injury.

Check out Machine Shops Phoenix to know more helpful information.